Comprehensive on-site refuelling and tracking solution for 3 Interconnected Diesel Storage Tanks at the Pump Using iPETRO Pro FMS.

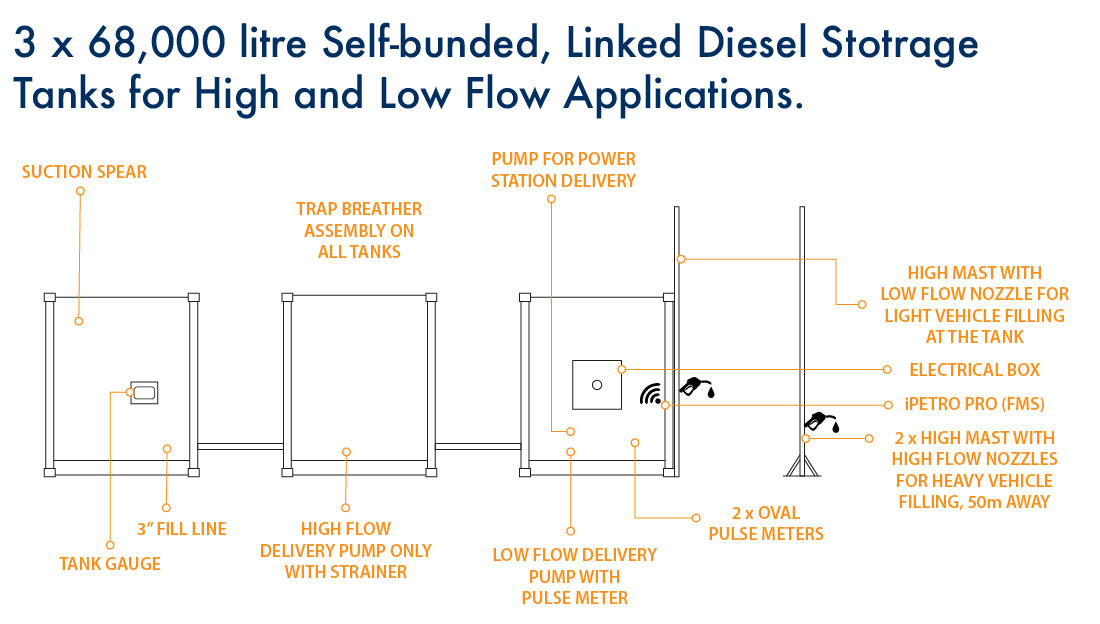

Our client approached us with the need for a comprehensive on-site refuelling and tracking solution for their fleet of vehicles, which included both high-flow and low-flow vehicles. The proposed solution involved linking three Bulk Diesel Storage Tanks, providing a total capacity of over 204,000 litres of Diesel.

Monitor Dispensing Volumes from 3 Interconnected Diesel Storage Tanks at the Pump Using iPETRO Pro FMS

To meet this challenge and provide real-time monitoring and tracking of all fuelling transactions, we installed an iPETRO Pro system. This system effectively captures and saves all the data on the iPETRO Cloud Pro website. This cloud-based solution not only ensures real-time access to fueling data but also offers powerful reporting capabilities, fuel level monitoring, and tracking software. This provides our client with a clear, up-to-the-minute view of what is happening on-site at all times.

With the iPETRO Pro FMS in place, our client now has precise control over dispensing volumes from the three interconnected diesel storage tanks at the pump, guaranteeing efficient and accurate fuel management for their operations.

The setup at the site includes two types of refuelling stations: one for light vehicles at the tanks and another for heavy vehicles situated 50 meters away with two high mast re-fuelling points. Additionally, an additional generator feed was added to the tank configuration, making it a multi-function re-fuelling and dispensing solution.

The iPETRO Pro Fuel Management System (FMS) is designed to record transactions from both the high-flow and low-flow stations, as well as the generator feed. This data can be analysed by the client to make informed decisions regarding their fleet’s fuel consumption and usage.

PETRO’s in-house engineers were responsible for designing all pipework and electrical components, and the installation was carried out by our Hazardous Zone Qualified team of electricians. All installations and equipment provided by PETRO are certified to meet required safety and environmental standards.

Additionally, the client was supplied with an 11,000L self-bunded Cube Tank for the storage of waste oil and a 1000L Cube for transporting diesel to where it’s needed. PETRO’s modular design approach allows for easy scalability, so the system can be adjusted according to the project’s changing requirements.

It’s worth noting that all the dispensing, monitoring, and gauging equipment provided by PETRO is custom-installed to meet the specific requirements of the client, ensuring an efficient and tailored solution for their refuelling needs.