The iPETRO Link-Gauging Communication Device sets the standard for comprehensive solutions, encompassing fuel cleanliness assurance, tank condition monitoring, fuel system management, and advanced pressure sensing.

What sets the iPETRO Link apart is its proactive monitoring capability, which diligently identifies potential issues before they can escalate into significant challenges for your business. This foresight not only streamlines the resolution process but also prevents any degradation in performance.

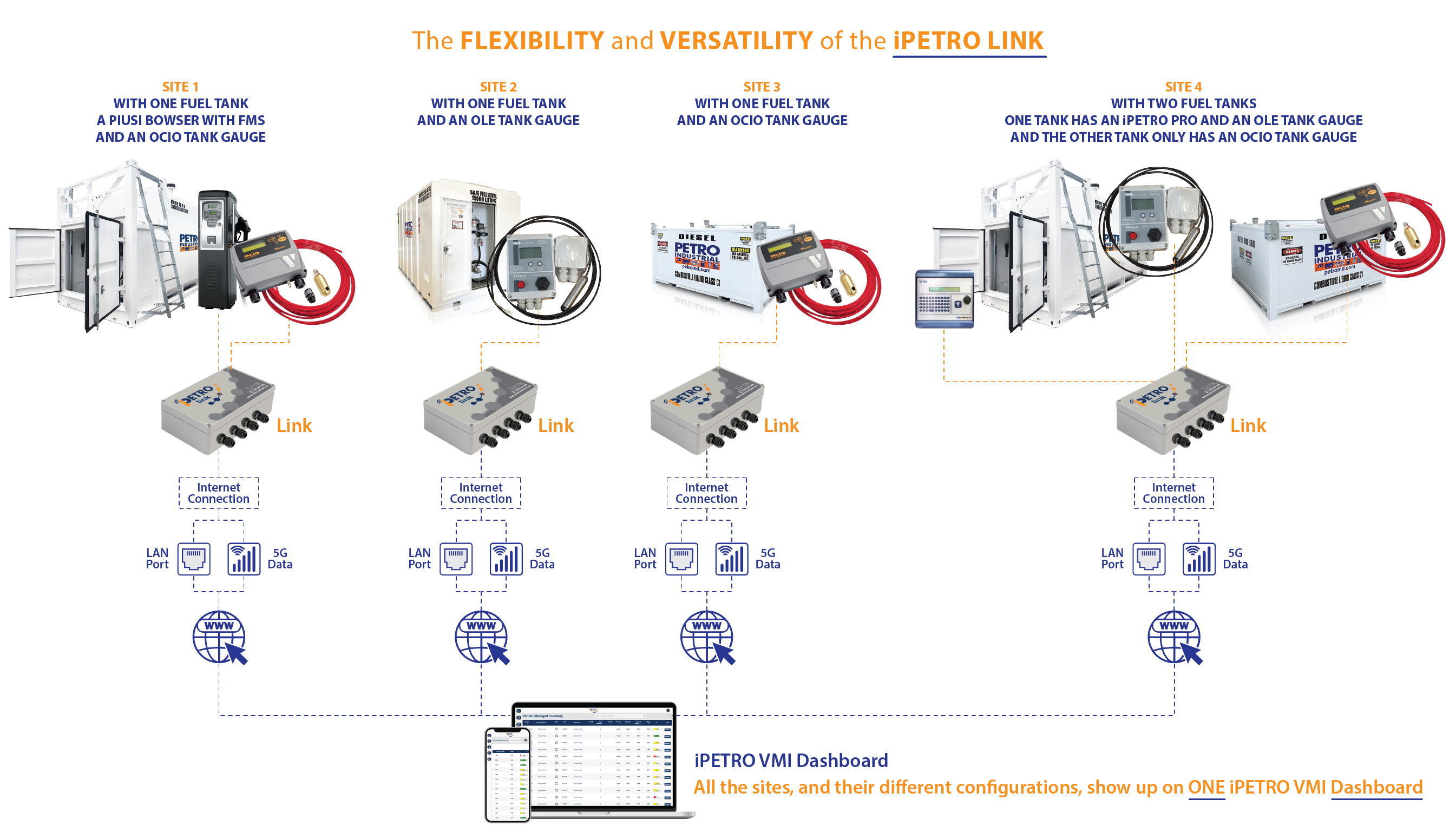

Ideal for locations with substantial liquid storage, such as refineries, water treatment facilities, petrochemical industries, distribution terminals, and depots, the iPETRO Link-Gauging Communication Device seamlessly integrates with existing management systems, whether they are OLE, OCIO, PIUSI, iPETRO, GILBARCO or other brands. This integration empowers you with complete control over all your sites or depots, regardless of your geographical location.

Enjoy multifaceted customisable configuration options, easy installation, and exceptional service for tank gauging systems. The iPETRO Link is the only solution on the market that offers not only Fuel management but also Tank Monitoring and Fuel Cleanliness capabilities.

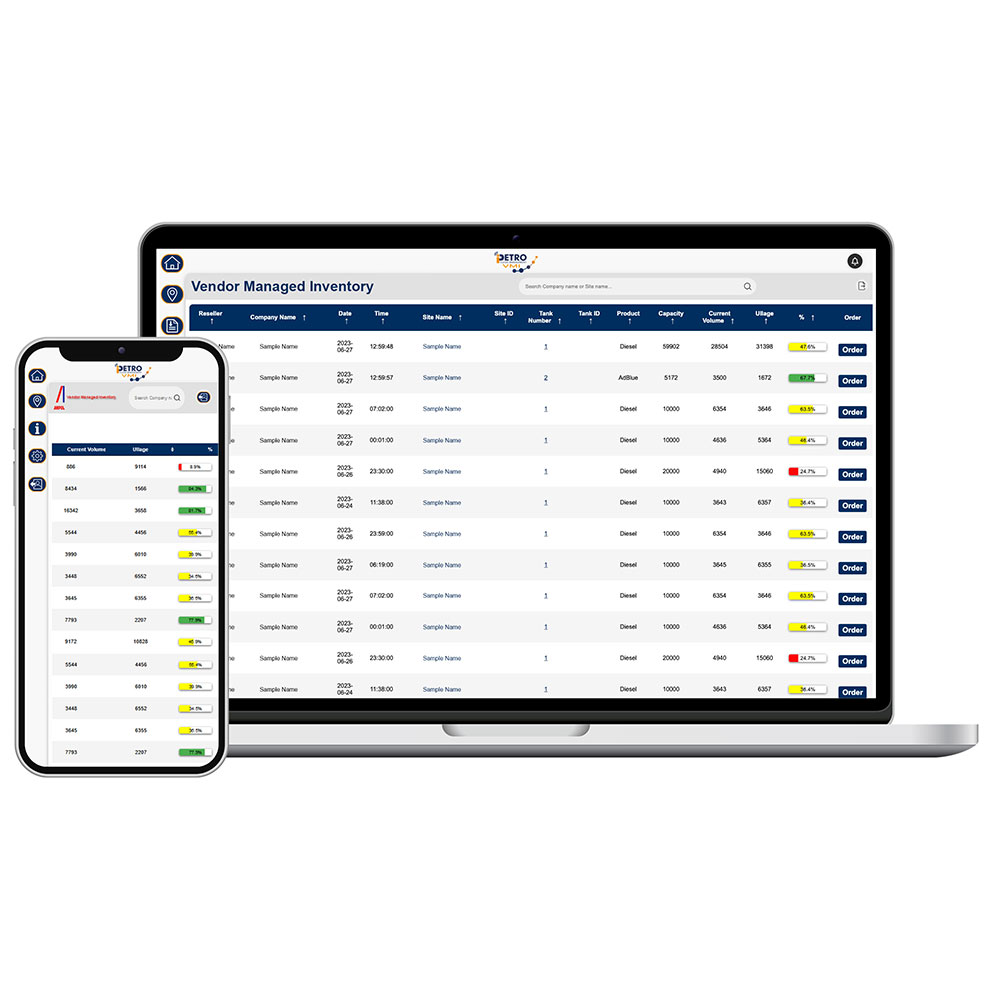

The system integrates straight into the iPETRO VMI dashboard, making it an effortless experience to manage all your project data, reporting, and notifications from one unified platform. Regardless of the number of locations!