Service Station Style Refuelling Depot with the iPETRO Fuel Management System

PETRO and iPETRO were approached by a logistics company with a request to design, develop, and commission a refuelling depot equipped with an FMS (Fluid Management System). The objective of the project was to create a facility capable of on-site diesel and AdBlue pumping for their extensive fleet of trucks. The solution needed to offer complete control and management of dispensing activities and wet stock levels, all while meeting rigorous compliance and safety standards.

The solution

PETRO and iPETRO provided a single site featuring multiple dispensing points and a split-compartment storage tank accommodating both diesel and AdBlue.

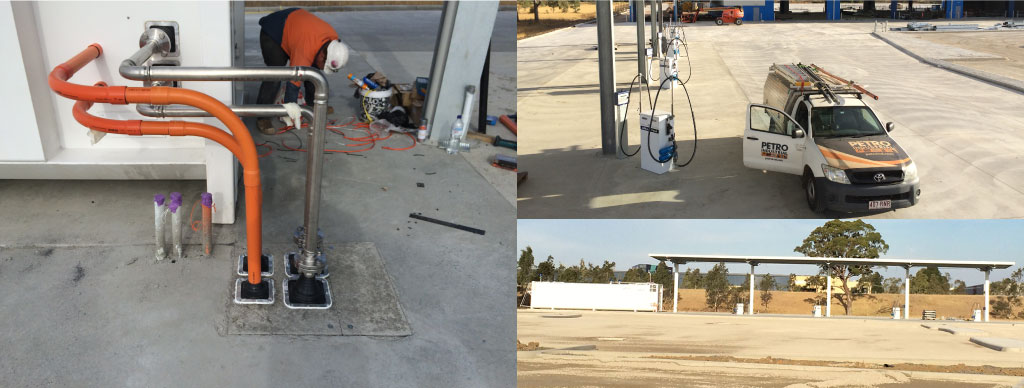

PETRO installed a PT Series 110,000L split compartment tank with an integrated pump bay housing. The tank was partitioned into two compartments, with 90,000L designated for diesel and 10,000L for AdBlue. Four dual dispensing bowsers were seamlessly connected to the tank and integrated with the cloud-based iPETRO Pro Fluid Management System.

The iPETRO Pro Fluid Management System offered versatility by enabling the connection of four additional remote consoles to the system. This meant that the client only needed to invest in one fuel management system to oversee all four dispensers at the site. Data collected by the four remote consoles was transmitted to the iPETRO Pro Console, where it was stored in real-time on the iPETRO Pro Cloud-Based Website. This setup allowed the client to access and manage all dispensing stations, drivers, vehicles, and stock from anywhere in the world with internet access. Additionally, the system provided valuable reports to aid in future planning and budgeting.

Furthermore, the client had the option to connect an iPETRO Pay Console to the iPETRO Pro FMS, enabling on-site fuel sales and generating additional income from their investment.

On Line Cloud Based iPETRO Fuel Management System

Forecourt Style Fleet Re-fuelling Depot with Fuel Management System

PETRO’s team of dangerous zone qualified technicians handled all the electrical work, design, and installation. The integrated pump bay housed the electrical control box, pump, tank gauging equipment, and filling point, ensuring a certified and industry-standard installation.

The fuel storage tank installation involved placing the PETRO tank with the integrated pump bay next to the transition pits. Fuel was pumped from the tank into the pit and then transferred to an underground double-containment pump, which distributed the fuel to the various dispensers. The pump bay within the tank featured two high-flow transfer pumps with strainers, one for diesel and one for AdBlue off-loading into the self-bunded split compartment tank.

Overall, the solution provided the client with easy and fast fleet re-fuelling, full control at multiple dispensing points, and efficient management of fuel and stock levels through the iPETRO Pro Fluid Management System.

Installation by qualified dangerous zone technicians

iPETRO has a solution for you! Our FMS systems are designed to bring ease of mind and confidence to our customers.

Talk to our project division to determine what is the best solution for your scope.