Fuel Depot with iPETRO fuel management system & dispensing points

PETRO and iPETRO were approached by a logistics company to create an advanced Fuel Depot and fuel management system. This system needed to accommodate multiple refuelling points and a comprehensive cloud-based fuel management solution.

Here’s what we designed:

- Multiple Dispensing Points: The Truck Depot features several dispensing points, allowing multiple vehicles to refuel simultaneously. This reduces waiting times and enhances overall efficiency.

- Bulk Fuel Storage Tanks: To ensure an ample fuel supply, we installed two 110,000L Self-bunded PT-Series Tanks on either side of a 20,000L Self-bunded Adblue Tank. These tanks store both diesel and Adblue fuels.

- Pre-Constructed Canopy: We added a pre-constructed canopy over the dispensing points and fuel storage tanks. This canopy shields the equipment and vehicles from the elements during refuelling.

- iPETRO Fuel Management System: At the core of the operation is the iPETRO Fuel Management System. This advanced system efficiently monitors and controls all dispensing points. It tracks fuel levels, consumption, and transactions, ensuring effective fuel inventory management and preventing unauthorized access.

- Electrical Design and Installation: Our highly qualified engineers took care of all electrical aspects, guaranteeing a reliable, safe, and compliant electrical system.

- Hazardous Zone Qualified Installation Team: PETRO’s Hazardous Zone Qualified installation team handled the installation process, crucial for fuel facilities like the Truck Depot. Their expertise ensures safety and compliance with hazardous zone regulations.

By integrating these components, the Truck Depot efficiently refuels its fleet while prioritizing safety, convenience, and effective fuel management. It offers a seamless refuelling experience for trucks and optimizes overall fleet management efficiency.

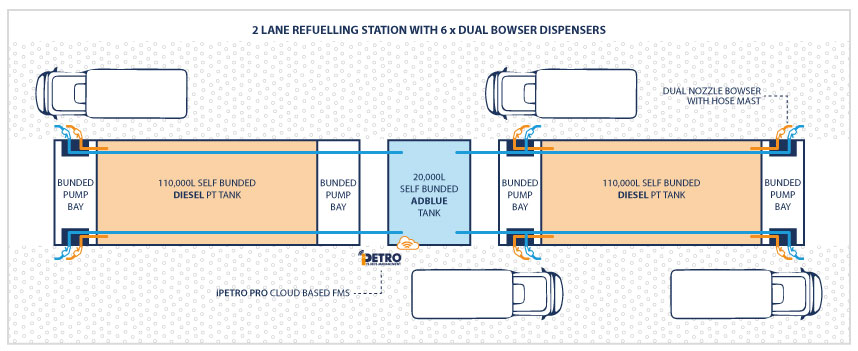

Design Overview:

- Layout: The design features two refuelling lanes, each with multiple dispensing points on both sides of the tanks.

- Dual Refuelling Stations: Each lane boasts three dual refuelling stations capable of dispensing both fuel and Adblue from a single dispenser. Adblue is an emissions-reducing fluid used in diesel engines with Selective Catalytic Reduction (SCR) systems.

- Adblue Tank and Pump System: The Adblue bulk fuel tank supplies liquid to each PT Series bulk fuel tank’s Pump Bay. Every PT tank is equipped with 3″ road tanker unloading kits and two submersible pumps (four in total), each capable of pumping over 100 litres per minute to the dual dispensers.

- High Mast Delivery Hoses: Delivery hoses are mounted on high masts for durability and ease of use.

- iPETRO Pro Fuel Management System: All six stations are seamlessly connected to PETRO’s Cloud-Based iPETRO Pro Fuel Management System. This system records and stores all dispensing activities for both fuel and Adblue. Each truck driver receives a personalized code to activate the pump, enabling precise tracking of individual driver activities.

- Integrated Tank Gauging System: The iPETRO FMS is linked to an integrated tank gauging system, allowing real-time tank level monitoring from anywhere with internet access. Email alerts are sent when tank levels run low.

- Powerful Reports: The iPETRO Pro FMS provides robust reporting capabilities, facilitating future planning and budgeting.

In summary, this design offers a comprehensive and advanced solution for efficiently managing the refuelling process, ensuring streamlined operations, and tracking fuel and Adblue usage for each driver and vehicle.

Take FULL CONTROL with the iPETRO Pro Fuel Management System!

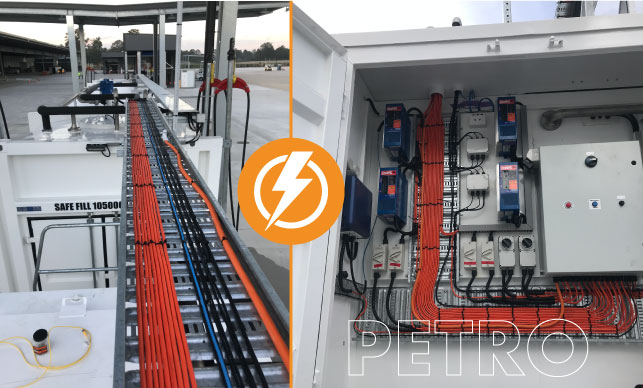

PETRO’s electrical design work is at the forefront of technology and is conducted by our team of skilled electrical engineers. Having experts handle electrical installations is vital to ensure safety, efficiency, and compliance with regulations and certifications.

Our “Hazardous Zone Qualified installation team” is well-prepared to manage installations in potentially risky or dangerous environments. This is particularly important in industries where electrical equipment may be exposed to flammable substances, chemicals, or other hazardous conditions.

We take great pride in our meticulously executed installations, which include the incorporation of Control Boards. Attention to detail and quality are top priorities for PETRO. Control Boards are essential components within electrical systems, providing the means to monitor and manage various aspects of system operation.

Emphasizing compliance with relevant regulations and certifications is also of paramount importance. Electrical installations must adhere to safety standards and industry-specific regulations to prevent potential hazards and legal issues.

In conclusion, PETRO’s approach to electrical design and installation is unwavering in our commitment to providing safe, reliable, and compliant solutions for our customers. This commitment holds particular significance in industries where electrical systems play a significant role in day-to-day operations.